The Dry Down Hoax

Have You Been Fooled?

Almost everyone has heard of or performed the dry down test. You know, the one where the manufacturer tells you to pour some undiluted chemical into a concaved glass full-strength. This test is shear brilliance from a marketing point of view. It shows off a particular feature of their product. How it won’t leave a sticky residue that promotes rapid resoiling. However, there are many problems with this test in its current protocol.

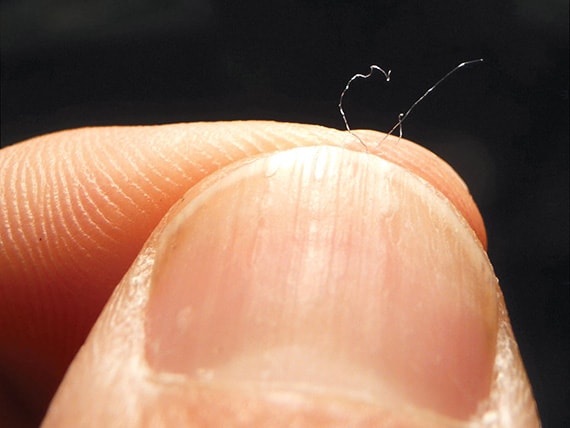

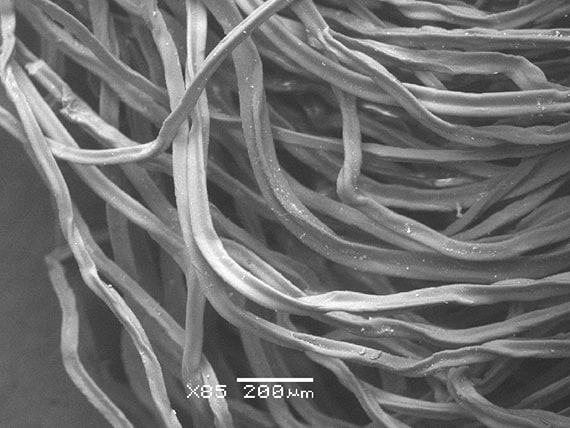

First, you never use your chemical full-strength, do you? You never leave a coating of chemical on the carpet fiber an 1/8” to a 1/4” thick like in the bottom of a glass. This is hundreds to thousands of times thicker than what would remain on a carpet fiber after cleaning. Here’s an exaggerated example, but I think you will get my point. Go outside and stand up a broom or shovel against the wall. Now take your garden hose, pressure washer, fire truck or whatever you want that sprays and spray the handle of the broom or shovel. You can spray a gallon or a thousand gallons on the handle it won’t make a difference. How much will stay on the handle? In other words, how thick will the liquid coating be? The answer: Not very thick. Gravity and surface tension will make sure of this. Now let’s look at a carpet fiber – in many cases, thinner than a human hair. How much of your encap will adhere to the vertical fiber? The answer: A very thin microlayer. So why do a test that uses chemical full-strength up to a 1/4” thick in a glass when in the real world you never get anywhere close to that. Why use a test designed to market a feature, not the reality of real world usage of the product?

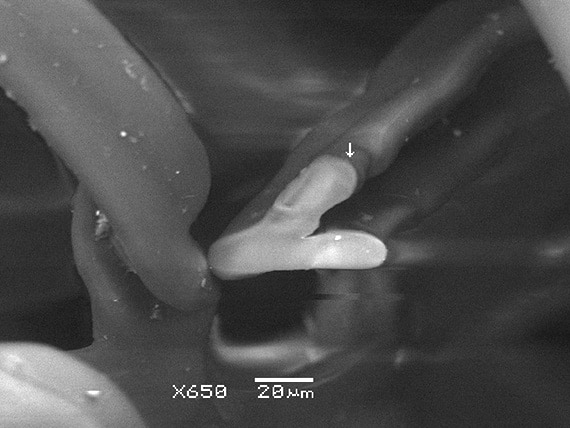

Imagine how thin the polymer is on this trilobial shaped carpet fiber magnified at 650x.

Did you know that the coating on a carpet fiber of encap polymer is under 1 micron thick? To put this into perspective, a pin head is 2 millimeters. A drop of water on a microscope slide is approximately one millimeter. A micron is 1,000 times smaller than 1 millimeter. We’re talking about a coating on the surface of a filament of carpet fiber that measures about 50 microns (40xs smaller than a pinhead) or a third the diameter of a human hair. So to pour the chemical full strength into a glass or on a plate for the currently accepted dry down test is 1,000 to 10,000 times thicker than the use of a product in the real world!

The product used in real world conditions will not cement soil to the fiber. If poured in a glass the product may dry rather hard and would seem to not be easily removed. But again, in the real world the layer of polymer is so thin that it has to be exceedingly strong to encapsulate the soils and fibers when the polymer in real use is under a micron thick. So naturally, if you take this very strong polymer and enlarge the thickness of the coating like in the glass trick thousands of times thicker than in real world applications, then its strength would also increase making the test inaccurate.

Surround products may fail the dry down marketing test. But that’s Ok; the test was designed to have competitors’ products fail. Surround would also fail if you filled your cars radiator with it, as it was never designed and manufactured to be used that way. However, when used in the proper and designed for purpose, Surround exhibits excellent encapsulating properties. The majority of our new T2H Hybrid Polymer will in most cases vacuum off of the fibers in 3 to 6 vacuum cycles. This could be a week in an office building or several weeks in a home.

The Real Deal

The most realistic test uses carpet. Something that scratches, has fiber flexation, and can be walked on. Get a piece of carpet, I used nylon. Take a marker and section your carpet into several squares from top to bottom. Than work into the center from left to right your properly diluted encap samples. Let dry completely. Than take two pieces of tape and make a runway down the center from left to right. Open a vacuum bag or get a soil sample and apply it to the runway. Remove your tape and vacuum. You can get a pocket microscope from Radio Shack for a few bucks and examine your sample more closely. Also, how does the carpet look and feel? Place this test carpet under your desk or in a doorway for a few weeks. Does the runway resoil more quickly than the rest of the carpet?

Does it dry completely or smear when touched? (Make sure it is completely dry) Sprinkle on some dry soil – will it stick to it when dry? Is it clear, slightly clouded or very clouded? This will affect the brightness of the cleaned carpet. On dry, clean carpet, glide your hand over its surface. The carpet should feel like a cotton shirt out of the dryer. In other words, there should be no resistance when you glide your hand over the fibers. It should just feel smooth and soft, not sticky.

Although testing on a carpet takes more time and effort you are rewarded with much more info you can use to determine your encap selection.

This message has been brought to you from Bonnet Pro. A company with 30 years of real world cleaning experience and a never-ending goal of providing America’s cleaners with quality products, excellent service and truthful answers to their cleaning needs.

by John H. Klucznik, Founder of Bonnet Pro and Key Floor Care

Sign up to get the latest Bonnet Pro News & Exclusive Special Discounts

Sign Up to Get the latest Bonnet Pro News & Exclusive Special Discounts

Pick the Best Products & Shipping Deals

Touch HereGet the best product for your needs video

Product use chart

Get the most for your shipping dollars video

Click here.

Order Our Sample Packs

.Super SAMPLE PACK

These discounted sample packs help you explore Bonnet Pro products. Become the legend in your town.

Must Have Proprietary Bonnet Pro Technology

Must Have Proprietary

Bonnet Pro Technology